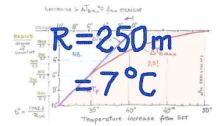

Measuring the track radius in degrees Celsius

On the shoulders of CWR giants In 1994 UIC (the International Union of Railways) and ERRI (the European Railway Research Institute) set up a committee of specialists – D202 – to develop an international standard code for laying and maintenance of continuous welded rail track. Various research institutions and national railway administrations provided a complex…